Stretch Wrap Buyer’s Guide: Everything You Need to Know

Release time: 2026-01-04

Table of Contents

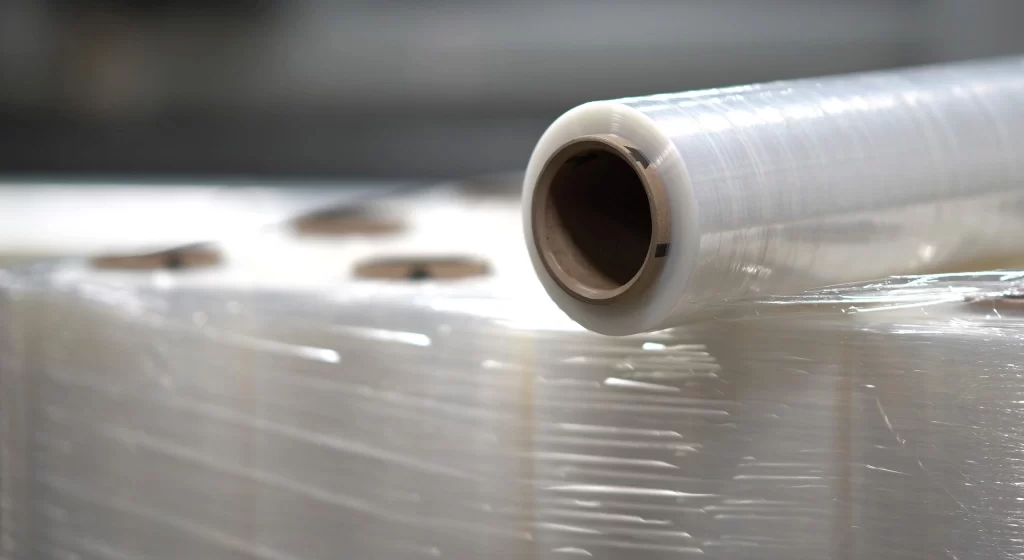

Stretch wrap is an essential tool in packaging and shipping industries, widely used to secure and protect products during transportation and storage. Understanding the ins and outs of stretch wrap can help businesses make informed decisions that enhance efficiency and reduce costs. In this buyer’s guide, we’ll cover what stretch wrap is used for, the equipment needed, how to choose the right type, gauge considerations, and tips on application tightness.

What Is Stretch Wrap Used For?

Stretch wrap, also known as stretch film, is a highly elastic plastic film that is used to bundle and secure items together. It is commonly employed in various industries for:

- Protection: Stretch wrap protects products from dust, dirt, moisture, and damage during transit. It creates a barrier that safeguards against environmental factors.

- Stability: By tightly wrapping items, stretch film prevents shifting and movement, ensuring that products arrive at their destination intact.

- Unitization: Stretch wrap helps in creating stable loads by bundling multiple items into one unit, making it easier to handle and transport.

- Tamper Evidence: When used properly, stretch wrap can indicate whether a package has been tampered with, as any tearing or breaking of the film is easily noticeable.

- Space Efficiency: It allows for efficient storage by compacting items and optimizing space utilization in warehouses.

What Equipment Is Needed for Stretch Wrapping?

While stretch wrap can be applied manually, using the right equipment can significantly improve efficiency and consistency. Here are some common tools used in the stretch wrapping process:

- Manual Stretch Wrap Dispenser: A handheld device that allows operators to apply stretch wrap more easily and with better control than by hand.

- Semi-Automatic Stretch Wrap Machine: These machines rotate the pallet while the film is dispensed, providing uniform wrapping and reducing labor costs.

- Automatic Stretch Wrap Machine: Ideal for high-volume operations, these machines automatically wrap pallets, increasing speed and efficiency.

- Stretch Film Roll Holder: This helps keep the rolls of stretch wrap organized and accessible, reducing downtime during wrapping.

How To Choose the Right Stretch Film?

Selecting the appropriate stretch film is crucial for effective wrapping. Here are some key factors to consider when choosing the right stretch wrap:

- Type of Stretch Film:

- Standard Stretch Film: Ideal for general purpose use, offering good puncture resistance and load-holding capabilities.

- Pre-Stretched Film: More expensive but offers superior cling and reduced material use, making it an eco-friendly option.

- Colored Stretch Film: Useful for color-coding shipments or providing added security by obscuring visibility of the contents.

- Width and Length: Stretch films come in various widths and lengths. Choose a size that fits your product dimensions and wrapping needs. Standard widths range from 12 inches to 80 inches.

- Cling Properties: Some stretch wraps have higher cling properties, which allow them to stick to themselves without adhesive, providing a tighter hold on the wrapped items.

- UV Resistance: If products will be stored outdoors or in direct sunlight, opt for UV-resistant stretch films to prevent degradation.

What Gauge Stretch Wrap Do I Need?

Gauge refers to the thickness of the stretch film, and it plays a critical role in determining the strength and durability of the wrap. The most common gauges range from 15 to 120, with lower numbers indicating thinner films. Here’s how to determine the right gauge for your needs:

- Lightweight Loads: For lighter items or short-term storage, a film with a gauge of 15-20 may suffice.

- Medium Loads: For standard warehouse products, consider a gauge of 20-30.

- Heavy Loads: For heavier items or long-term storage, opt for thicker films in the 30-80 gauge range.

- Specialty Applications: In some cases, such as when wrapping sharp or irregularly shaped objects, a thicker film (above 80 gauge) may be necessary to prevent punctures.

How Tight Should Stretch Wrap Be?

The tightness of stretch wrap is critical for ensuring product security without causing damage. Here are some guidelines to follow:

- Avoid Overstretching: While it’s important to wrap tightly, overstretching can cause damage to the film and the products being wrapped, leading to potential breakage or deformation.

- Balancing Tension: Aim for a balanced tension that secures the load without creating excessive pressure. A good rule of thumb is to wrap until the film begins to pull taut but does not distort the shape of the items.

- Layering Technique: Consider using multiple layers of film for added security, especially for larger or heavier loads. Ensure each layer overlaps slightly for a secure hold.

Conclusion

Choosing the right stretch wrap and applying it correctly can significantly impact the safety and integrity of your products during shipping and storage. By understanding its uses, equipment options, selection criteria, gauge considerations, and application techniques, you can optimize your packaging process. Whether you are a small business or a large manufacturer, making informed choices about high performance stretch wrap will lead to improved efficiency and cost savings in your operations.

Frequently Asked Questions (FAQs)

Q: What Is the Shelf Life of Stretch Film?

A: The shelf life of stretch film varies depending on factors such as storage conditions and film quality. Generally, when stored in a cool, dry place away from direct sunlight and extreme temperatures, stretch film can have a shelf life of 1 to 2 years.

Q: Can I Use Stretch Film for Food?

A: Food-grade stretch films are available for the safe and hygienic packaging and storage of food products. Ensure the stretch film is labeled explicitly as food-grade and complies with food safety regulations to prevent any contamination risks.

Q: Can Stretch Wrap Shrink?

A: Stretch wrap does not shrink. It is designed to stretch and conform to the shape of the items being wrapped, providing secure containment and stability during transportation and storage.