How to Properly Use Stretch Film for Packaging

Release time: 2025-08-04

In the industrial field, using stretch film to wrap goods ensures safe transportation and significantly improves logistics efficiency. This has become an inevitable trend in modern industry. The use of industrial stretch film packaging is far from just simple wrapping. Hefei Lihe, based on a deep understanding of material properties and customer practices, has summarized the key steps for efficient application.

Four Steps to Achieve Efficient and Secure Packaging

Equipment Selection and Matching:

- Manual Application: Suitable for small batches, irregular goods, or reinforcement and repair. Lihe offers a variety of hand stretch films with different thicknesses and adhesiveness to meet flexible needs.

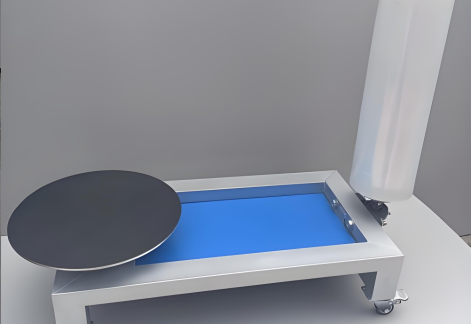

- Semi-Automatic Application (Pallet Turntable): Significantly improves pallet packaging efficiency. The operator holds the film dispenser and wraps it around the rotating pallet, ensuring uniform force distribution.

- Fully Automatic Application (Stretch Wrapping Machine): A fully automated production line can integrate high-performance stretch film, precisely controlling pre-stretch ratio, tension, wrapping layers, and top/bottom reinforcement circles, achieving unmanned, efficient, and consistent packaging. Its optimized composite film production line technology ensures high strength and uniformity of the film.

Wrapping Method and Coverage:

The classic top-to-bottom spiral wrapping method ensures the goods are tightly wrapped into a solid unit. Special attention should be paid to reinforcing the bottom and top of the goods (wrap a few more layers) to prevent the edges from loosening.

Tension Control:

Tension is the key to successful packaging. If it is too loose, the goods won’t be stable; if it’s too tight, it could deform the goods or cause the film to break. Lihe’s stretch film is designed and produced with a precise formula and production control, offering excellent stretch recovery performance and tear resistance. With its CNC control technology, it helps users easily find the optimal tension balance point, ensuring both firmness and safety.

Pre-Stretching Technology Application:

The film is pre-stretched by the equipment (far beyond manual stretching limits) before wrapping the goods.

- Significant Material Savings: For the same wrapping effect, the film usage can be reduced by 30%-50%, directly lowering costs.

- Enhanced Binding Force: After pre-stretching, the film’s shrinkage force is greater, making the wrapping tighter and improving the stability of the goods.

- Increased Efficiency: Reduces the frequency of film roll replacement and speeds up the packaging process.

Hefei Lihe Packaging Materials Co., Ltd. not only provides high-quality industrial stretch film products but also offers comprehensive services, including equipment selection advice, application technical support, and customized solutions. The company continuously invests in R&D and innovation (holding patents such as the optimized composite film production line), relying on intelligent manufacturing to achieve an annual production of 19,000 tons of efficient and stable supply, promoting the green and sustainable development of the packaging industry.

Choose Hefei Lihe industrial stretch film to safeguard the safety of your goods and logistics efficiency.